GT is expert in manufacturing and designing of carbon based materials for many applications.

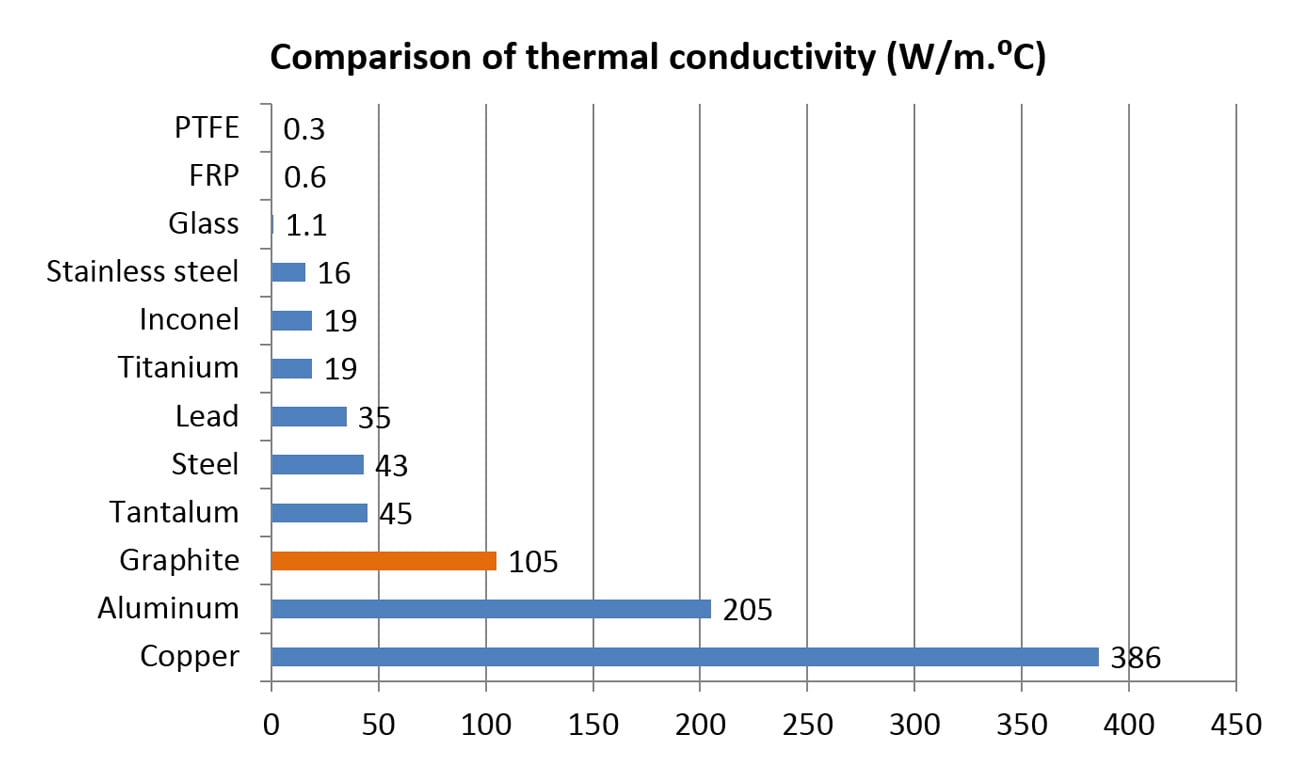

Graphite is characterized by its high level of corrosion resistance and its thermal conductivity is much greater than most comparable corrosion resistant materials.

It is commonly believed that impregnation process does change the inner thermal conductivity of graphite. That’s wrong because air is replaced by resin during the impregnation process. Air is worst conductor than resin.

What could reduce the heat conductance of the material is the remaining layer of resin on the surface of the graphite if any,

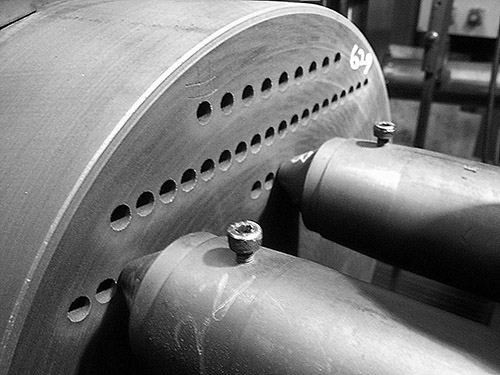

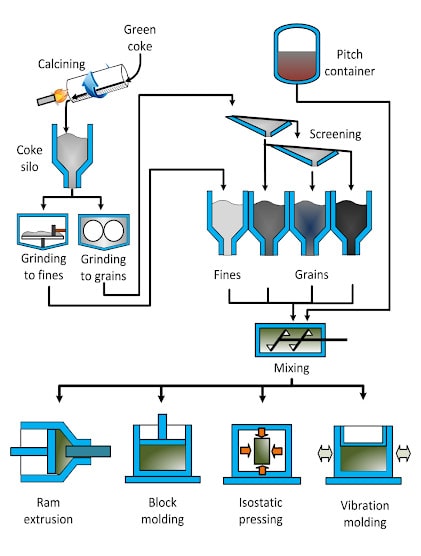

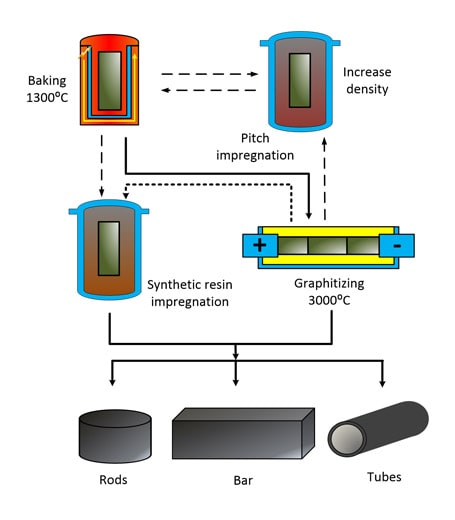

Manufacturing process, of graphite raw material, requires a lot of energy during compression, baking and graphitization. A very long process which can take several months.

GT use 3 types of graphite combined with 3 type of impregnant.

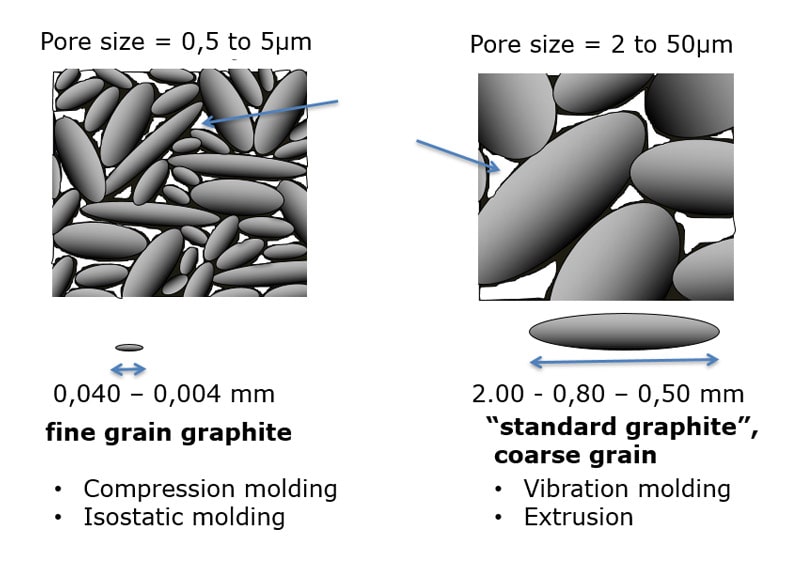

| Coarse grain | Fine grain | Ultrafine grain | |

| Grain size | 0.80 – 0.50 mm | 0.043 – 0.020 mm | 0.010 – 0.004mm |

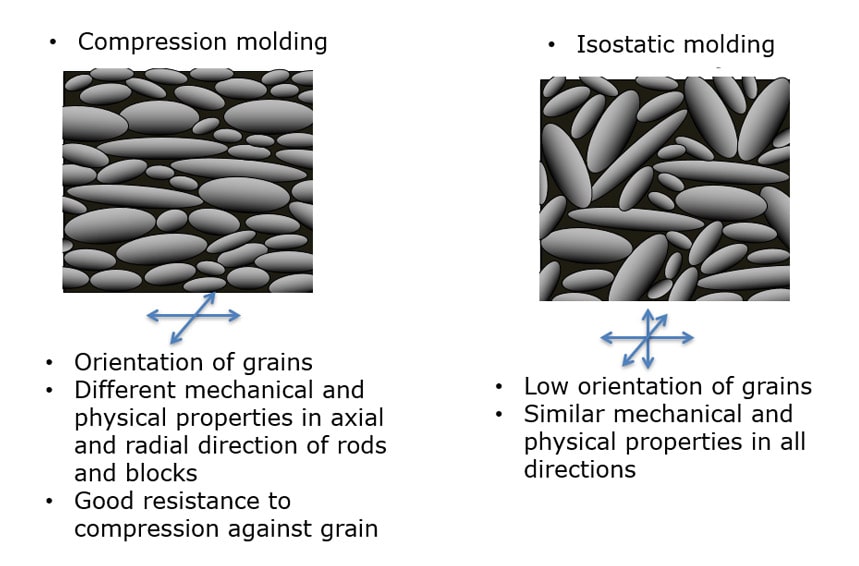

| Procede | Extruded | Compression molding or isomolding | Isomolding * |

| Density (1) | 1.71 – 1.75 | 1.72 – 1.90 | 1.75 – 1.92 |

| Thermal conductivity | 90 – 130 W/mK | 90 – 130 W/mK | 90 – 130 W/mK |

| Mechanical resistance | Medium (1) | High to very high | Very high |

| Corrosion resistance | High | High | High |

| Origin | Worldwide | Worldwide | TOYO TANSO or SINOSTEEL |

| Price ratio | 1.0 | 1.3-2.0 | 1.5/3.0 |

- Densified after graphitization

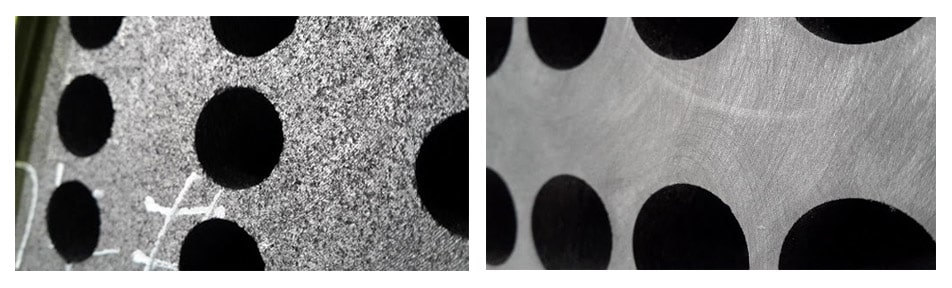

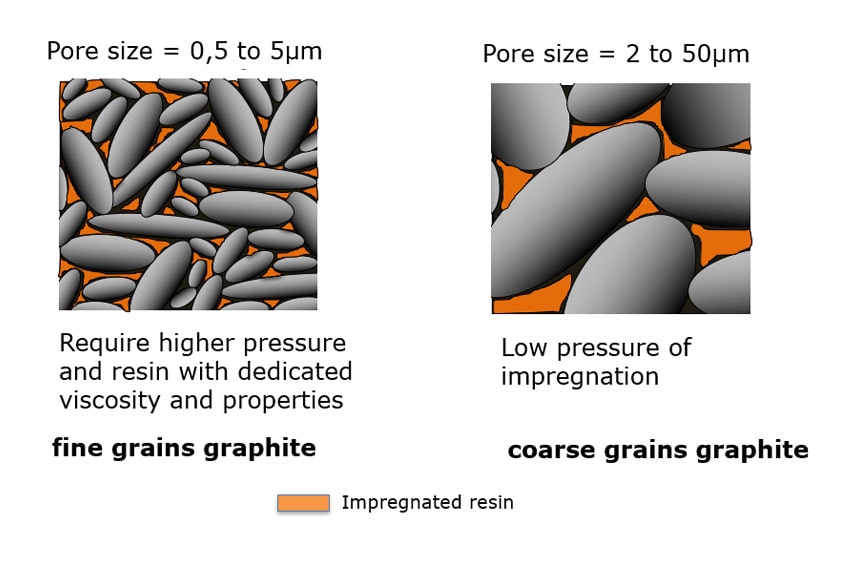

Impregnation process consist to fill the inner porosity of graphite (which is between 5 to 20% depending of the grade) with another material. Usually liquid resins are forced to penetrate into this porosity through the action of pressure and time. Hereunder a comparison between impregnaiton of 2 types of graphite structure.

For chemical processes equipment GT supply 5 main grades of graphite materials.

| GT-KELITE | GT-KELITE+ | GT-FLON / GT OXY FLON | GT-CARB(+) | |

| Type graphite | Coarse grain | Fine / Ultra fine grain | Fine / Ultra fine grain | Standard /Fine/Ultra fine grain |

| Impregnant | Phenolic | Phenolic | PTFE | Carbon |

| Relative mechanical resistance | 1 | 1.5 – 3 | 1.5-1.8 | 1.5 – 2.5 |

| Corrosion resistance | Good | Better | Excellent | Excellent |

| Thermal shock resistance | Low | Better | Excellent | Excellent |

| Recommended for… | Mild operating conditions (pressure, temperature, corrosion) | Higher pressure and temperature. Frequent thermal cycles | Highest corrosion (oxydative media) | Highest corrosion and temperature (non oxydative media) |

| Temp max (°C) | 160-180 | 180-220 | 300 | 500 / 1500 |

| Price ratio equipment (approx.) | 1 | 1.2-1.5 | 1.5-3.0 | 1.5-3.0 |

Get in touch here with us to know more.

Download brochures of Materials GT KELITE/ GT CARB/ GT FLON/ GT OXYFLON here