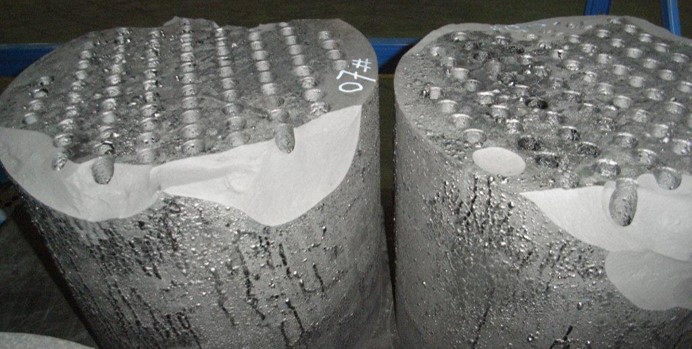

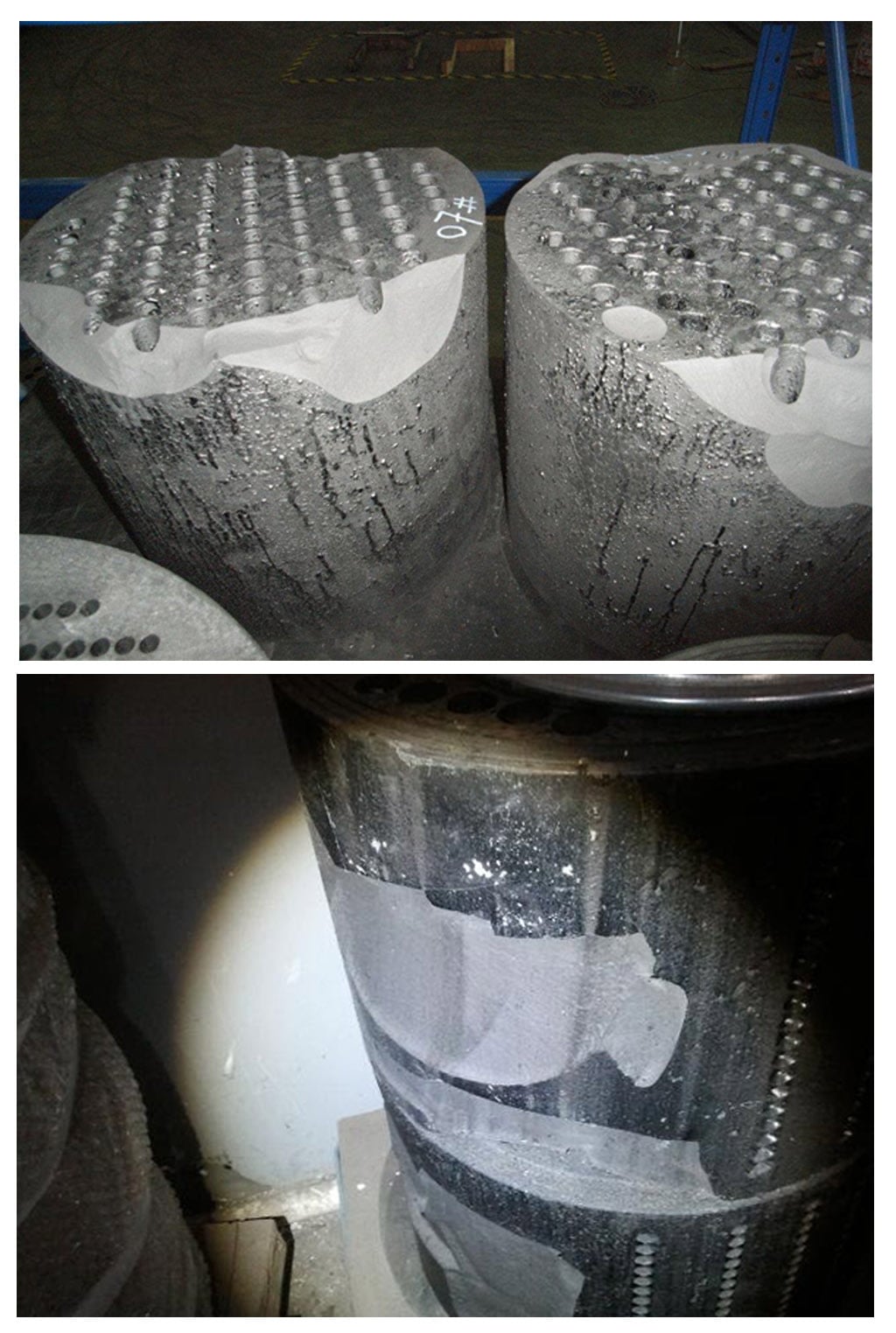

Thermal shock is a common problem when sequence of introduction of media in the equipment is not respected. This is critical when there is a temperature difference between the 2 media of more than 50°C.

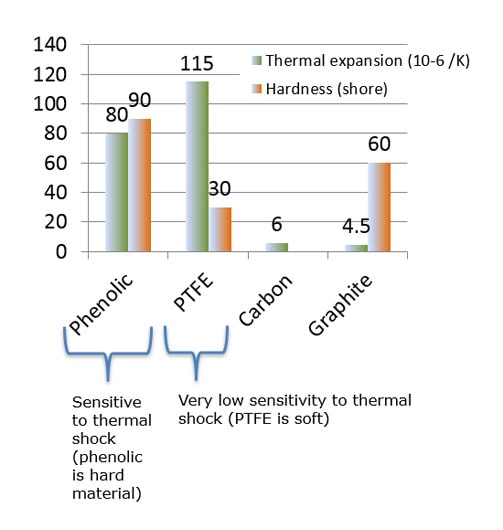

This is due to the inner structure of impregnated graphite. Traditional graphite have high porosity which is filled with a high content of phenolic resin. Phenolic resin is a material having a much bigger thermal expansion coefficient than graphite. Differential of thermal expansion during heating and cooling of equipment will generate inner stress which will reduce lifetime of graphite.

GT developped grade which can solve these problems.

GT KELITE+ with ultrafine grain is not sensitive to thermal shock at more than 100°C difference.

GT FLON and GT CARB+ are not senstive to thermal shock at more then 200°C difference

Thermal shock examples