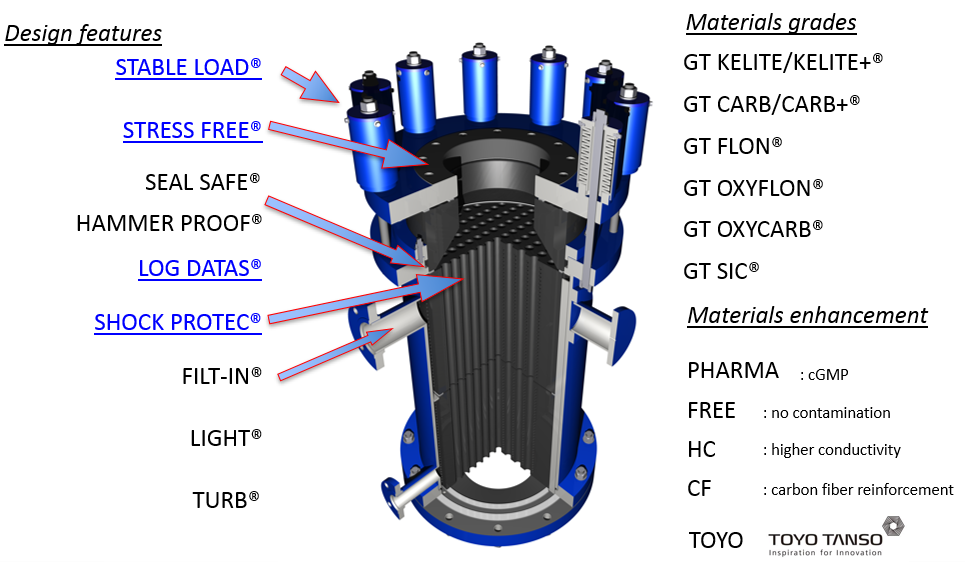

GT graphite equipment feature major unique technologies improvement which prevent main problem occurring during operations.

Our equipment are user friendly and allow mistakes from operation unlike most competitors supply.

| Name | Description | Recommended for… |

| SAFE SEAL | double sealing with leak detection | pharmaceutical / high purity process. |

| STABLE LOAD | spring box with stable load force during operation. Reduce by 90-95% graphite stress fatigue. | process with temperature difference between service/process more than 70°C. Long equipment. |

| SHOCK PROTECT | design of drilling which reinforce blocks mechanical resistance. | all processes. Steam and water hammer protection. |

| FILT-IN | mesh filter in service inlet nozzle to prevent water drop in steam or filter dirty media | steam heater, dirty service liquid media. |

| LOG DATAS | data logger for temperature, pressure, vibration to survey operating conditions | improvement of process, extension of lifetime, harshest process survey. |

| STRESS FREE | design of header without graphite nozzle in contact with external piping | all processes. Not used for temperature process>180°C and media which corrode glass. |

| TURB | Heat exchange coefficient enhancement | viscous media, small flow |

| LIGHT | long tie rods, oring service sealing, light structure | laboratory and pilot equipment. Lack of space for equipment installation. |

| C-HARD | Erosion protection | Pickling and phosphoric acid for fertilizer. All erosive process with hard particles. |

| HAMMER PROOF | Device to absorb waves of pressures surge | All equipment (even not in graphite) |

| GT TUBE-I | Tube with very smooth surface reducing fouling process. Tube without cemented junction up to 12m length. |

Long shell and tubes bundles. Dirty processes. Temperature under 160°C |

| P-Sensor | Pressure sensor which proof when level of pressure is exceeded | All equipment (even not in graphite) |

| Equipment option | Description |

| Decontamination | Cleaning equipment with solvent or distilled water |

| Clean in place | Installation spray nozzle for cleaning in operation |

| Inspection nozzle | Nozzle for process inspection. |

| Service side lining/coating | Protection of steel part from corrosion (rubber lining/fluoropolymers lining or coating, glass lining) |

| Service opening | Door for cleaning service side without dismantle equipment |

Contact us here to study how to improve lifetime and reduce your maintenance budget.

Download our guide to protect graphite equipment here.