GT provide the widest range of heat exchangers type combined with the widest range of material made of carbon.

Select the type of equipment in the menu to know more about it.

Hereunder, a selection of models of heat exchangers recommended for your process based on few operating parameters.

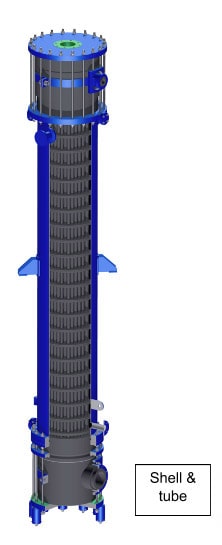

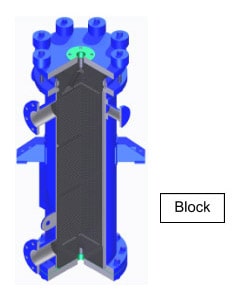

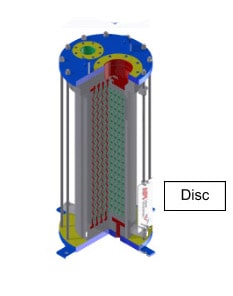

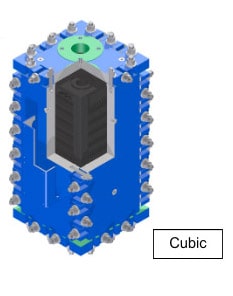

| Type | Dirty process | Liquid flow >500-700 m3/h | Oxidative media (3) | Low footprint | Low LMTD(2) |

| Block | YES | NO | YES | YES/NO | NO |

| Cubic | YES | NO | YES | YES | NO |

| Plate | NO | NO | YES | YES | YES |

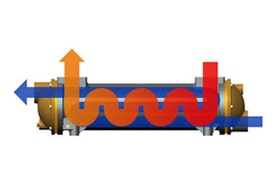

| Shell & tube | YES | YES | NO | NO | NO |

| Disc | YES | NO | YES(1) | YES | YES |

- only if discs with gasket, not cemented with phenolic glue

- LMTD – logarithmic mean temperature difference between 2 sides media

- Sulfuric acid >85%, nitric acid, peroxide,

You can also download guides to help you to specify the technical requirements for your projects.

Download Guide for chemical processes

Download Guide for pickling processes